| |

Cleveland

Tramrail by Gorbel:

A Name Built on Quality

Now we're bringing that same level of service to the Cleveland

Tramrail line of Tarca® Track and components. Cleveland Tramrail

has been the industry leader in the manufacture of patented track

monorail and under-hung crane systems since 1919. The addition

of the Cleveland Tramrail product line will allow us to provide

comprehensive solutions in higher capacities.

What do you gain when you choose Cleveland Tramrail?

• In depth knowledge of the material handling industry

• Accurate, on-time deliveries

• Ease of doing business made possible by our cutting edge

Web technology

• Quick Ship programs unmatched in the industry

|

• Superior customer service from a helpful, knowledgeable

team

• Consistently high quality products

• Proven track record in providing overhead lifting solutions

Cleveland Tramrail products continue to reflect the quality that

made Cleveland Tramrail the patented track leader, with the value

added customer service and support that made Gorbel " A Class

Above."

What is a Tarca® System?

Cleveland Tramrail's unique patented Tarca® Track System continues

to be the benchmark of the overhead material handling industry.

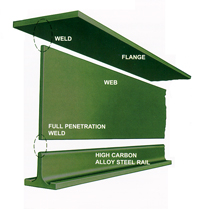

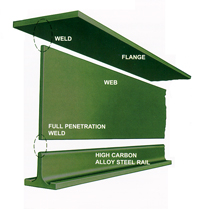

Its three piece welded construction is a compound section of a

mild steel top flange and web and a specially rolled high-carbon

steel lower rail. Tarca® systems are characterized by consistently

straight rail sections and durable, high quality Tarca® components.

Our Tarca® systems offer unmatched versatility, durability

and ease of installation.

|

Why Tarca®

Track Over Structural Steel Track?

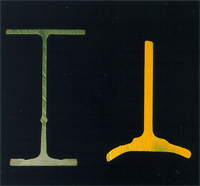

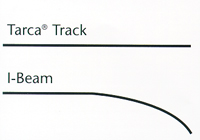

A structural I-beam is rolled from soft, mild steel according to

fairly loose steel mill tolerances. Its bevelled flange prevents

wheels from making balanced contact, causing uneven wear and a shortened

track life.

Cleveland Tramrail's unique Tarca® Track, with its special raised

tread and high carbon track, is superior to I-beams in strength,

durability and consistency. Our exclusive rails permit the use of:

|

|

• Underhung

carriers operating on a single straight, curved or inclined track

• Underhung cranes operating on two or more straight track

runways.

Tarca® Track has a mild steel top flange and web and a high

carbon steel lower rail with raised tread to resist peening. Continuous

welding adds rigidity needed to cope with bending and twisting

stresses of the most demanding applications.

The web and flange dimensions of each size are proportioned for

maximum strength and spanning efficiency.

|

| |

Tarca Track: Engineered for Crane Applications

Strong, Durable Rail

Tarca vs. I-beam

High carbon flange means longer track life

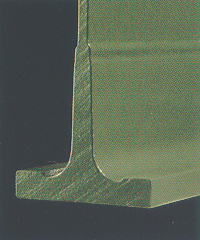

A common source of track wear is a process known as peening. Peening

is the gradual movement of metal over time, caused by the rolling

action of wheels. Because of I-beam's mild steel construction, peening

tends to occur unevenly, weakening the beam flange and restricting

smooth easy travel.

|

Tarca ® Track's raised tread design and extra hard alloy steel

construction slow down the peening process. The full width of

the raised tread wears evenly, extending track life well beyond

that of I-beams.

Our raised tread provide durability and superior safety

The raised tread on Tarca® Track is 20-25% of the Tarca®

rail thickness. And though this does add some strength, our stress

calculations do not include the strength added by the raised wearing

tread. That means you get even more strength and dependability

because the rated capacity of the track is not affected by wear.

Since I-beams have virtually no raised tread, their initial load

carrying capacity is in the total cross section. As a result,

capacity and safety are greatly reduced as soon as the tread begins

to wear.

100% weld penetration ensures quality

Tarca® Track is manufactured using stringent quality assurance

procedures. This is the basis for certifying 100% weld penetration

for maximum strength, safety and rigidity. Extreme care is taken

during track fabrication to maintain dimensional tolerances. Our

tracks are straight and true with minimum distortion, so:

• Installs are quick and easy

• Load distribution is uniform

• Tracks and components last longer

Stop Throwing Away Your Installation Dollars!

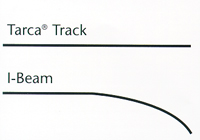

Our straight quality standards in manufacturing guarantee consistently

straight, high quality beams. Plate is cut to size and leveled

by precision machinery. Special equipment uses continuous welds

to insure absolutely straight, uniform track. Standard mill practice

dimensions for I-beams have tolerances more than twice those for

Tarca® rail. For example, allowable sweep per 10' of structural

beam may be as high as 1/4" while Tarca® rail is less

than half that at 3/32".

Is It Really Cheaper to Use an I-Beam?

Consider the time and money you're throwing away during installation:

redrilling holes and cutting, fitting, and shimming rails in order

to align I-beams that aren't straight. Our consistently straight

rails results in easy, predictable, cost effective installations.

Straight Rails Make System Expansions Easy

These tight quality standard even make system expansion and reorganization

easier and more cost effective. Consistently straight beams will

reduce labor costs when you want to expand a crane system or rearrange

a work area.

|

Our

Weight Is In All the Right Places

Efficient Design for Spanning

The thickness and width of Tarca®'s web and flange for each

size have been carefully engineered to maximize strength and loading

capacity while minimizing weight. Tarca®'s three piece welded

construction:

• Delivers maximum load carrying capacity to dead weight

ratios

|

|

• Provides ability to cost effectively span longer distances

• Eliminates costly additional supporting structures

• Reduces drag in manual system

I-beam simply can not match Tarca®'s carrying capacity to

dead weight ratio. Structural I-Beams are manufactured for a purpose

other than overhead material handling. Because of this, they are

manufactured to much looser mill tolerances than many crane and

monorail applications require.

Standardized Lower Flange

Standardized lower flange provides compatibility

Tarca® track features the same 3 1/4" wide lower flange

regardless of rail height or load carrying capacity.

• Allows systems to be easily expanded or rearranged

• Ensures compatibility of components

• Lower costs when suspension points vary

The lower flange of an I-beam increases in width and thickness

as its depth increases. Beams of different sizes are therefore

not compatible. The result? I-beam crane systems are costly and

difficult to expand or relocate.

|

| |

Rugged,

Long Lasting Components

Hardened wheels to ride on high carbon track

Our forged, heat-treated wheels are built to last. They provide years

of smooth, easy movement and reliable service. They have been:

• Designed to roll with minimal resistance (2 times easier than

I-beam)

• Machined to meet the surface of the track for consistent,

full contact and longer life

• Engineered to avoid flat spots for smooth, uniform rolling

|

Rugged end trucks and carriers

Cleveland Tramrail end trucks have been carefully engineered to

provide the finest performance with little or no maintenance.

Extended drive life

All gears and shafts in Cleveland Tramrail drives are made with

a remarkable alloy-steel that was chosen after long, grueling

tests. THis special alloy allows the drives to hold up to the

wear and tear of constant service. This adds many years of reliable

service to the motor head.

Flexible Suspensions

Flexible suspensions provide longer

system performance and lower maintenance costs

Tarca® Track is suspended using ball and socket connections,

permitting the track to float in all directions. This means it

can compensate for structural movement by allowing tracks to move

and adjust to crane wheel centers. This:

• Prevents damaging stress

• Dampens shock loads

• Allows for smoother operation

In other words, Tarca® rails can adjust to loads as they move,

enabling carrier wheels to maintain consistent contact. This "load

balance" of the wheels and components allows for longer life

with less maintenance.

|