| |

Tarca®

Rail

Tarca® Track features specially rolled high-carbon alloy steel

rail with raised treads welded to a steel flange and web.

Tarca® is designed to provide maximum spanning capability

for heavy loads while minimizing the weight of required material.

Its material properties resist peening and assure a longer operating

life than ordinary track designs.

|

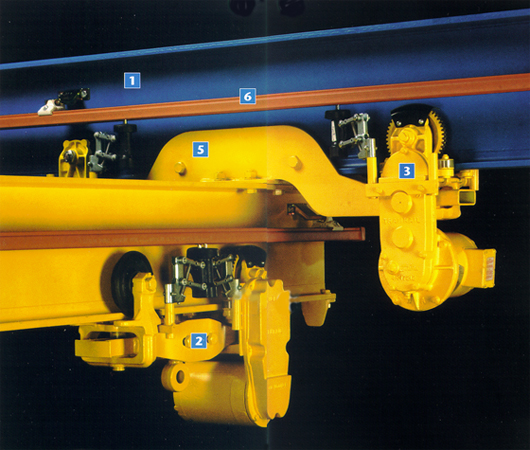

Carriers

(Trolleys)

Cleveland Tramrail carriers provide the connection between the

lifting device and the bridge. Our carriers are designed for years

of peak performance:

• The

wheel base is proportioned for smooth, vibration-free carrier

operation.

|

|

• Swiveling

yoke provides unmatched performance through curves and switches

on monorail systems, contributing to longer track life.

• Precision

manufacturing and specially designed wheels assure consistent

wheel to rail contact.

• The

extensive variety of our carriers provides endless flexibility

to tackle any application.

• The

manually driven carriers are also available.

|

| |

Motorized

Drives

Cleveland Tramrail's drives motorize the travel of carriers and

end trucks. We offer:

• A gear driven drive, the best choice for most applications

• A belt driven drive designed to be a lower cost alternative

to the gear driven drive

• A tractor driven drive for specialty systems, such as

pulling loads up a slope or for use in wet conditions.

Our drives were specially designed to make them long wearing and

easy to service.

|

• Guide

rollers equipped with anti-friction bearings align wheels on track

for easy movement

• Split frame construction for easy removal and reinstallation

|

Hanger

Assemblies

Our hanger assemblies provide a connection between the Tarca®

track and structural support..

• Our hanger rods are made of high-quality steel with cold-rolled

steel threads.

• Adjusting clamp fits a range of flanges

• Ball and socket design compensates for structural shift

|

|

• Teflon®

coated chair washers provide durable, long lasting performance

|

| |

End

Trucks

End truck with drive for motorized travel on runway

Cleveland Tramrail end trucks provide the connection between the

bridge and runway. These rugged end trucks give you smooth, easy

travel with little or no maintenance.

One advantage of our end trucks are their wheels. While other

manufacturers have fixed wheels on their end trucks, our articulating

wheels allow for irregularities in track and runways. End trucks

can also be manually driven.

|

SAFPOWRBAR®

Electrification (Brackets, Collector Shoe and Bar)

Cleveland Tramrail SAFPOWRBAR® Electrification is used to deliver

electric power to drive and hoists. This rugged, durable system

is made to perform in the most demanding applications and environments.

• Inverted U-shaped conductor bars enclosed by flame resistant

insulated covers

• Fiberglass molded insulators for double insulation, making

them safer and more efficient

|

|

• Sliding

current collector shoes inside the bars make positive, continuous

contact with three surfaces of the bar no longer life and easier

maintenance.

This bar is UL approved and perfect for bridge and monorail systems.

It provides unmatched performance in complex monorail systems

that involve switches and curves.

|

| |

End

Stop

End stops are required and must be provided at the ends of the

carrier or trolley travel and at the end of crane travel on runways.

Our end stops are unique in that they strike the end of the load

bar, rather than the wheels. This prevents the wheels from absorbing

the force of the load and reduces the areas of wear.

We offer standard wheel end stops for lighter applications and

rubber, spring or hydraulic bumpers for higher speed conditions.

|